Sheet Metal Cutting Plan Software

Posted By admin On 17.09.19Sheet metal design software considers the fabrication methods needed for manufacturing. As you create flanges and add bends, the sheet metal design software will accurately represent the flat pattern required. The flat pattern can be used to document and manufacture associatively as the design changes. Software To Grow Your Business. RADAN is acknowledged as one of the world's leading PC based CAD CAM software solutions for the Sheet Metal Cutting industry. It offers a unique combination of applications for Punching, Profiling, Bending, Design and Production Management for Sheet Metal Fabrication. Sheet metal design software considers the fabrication methods needed for manufacturing. As you create flanges and add bends, the sheet metal design software will accurately represent the flat pattern required. The flat pattern can be used to document and manufacture associatively as the design changes.

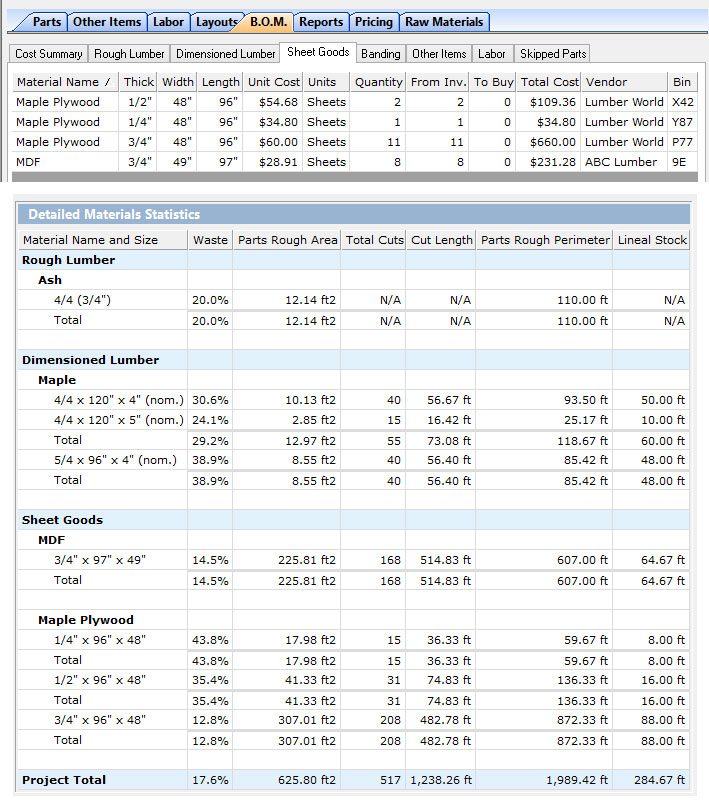

We have been using Cutlogic 1D and CutLogic 2D since 2007 with great success. With the continually rising cost of steel every inch of scrap means lost revenue. Cutlogic has helped to minimize this. The programs are very easy to use and have great functionality. Cut lists and parts labels can be printed which allows our shop to keep better track of production.

Finally, the support received is excellent and new, helpful features have been implemented over the past few years. We would highly recommend this program to anyone who needs accurate cutting plans in 1D or 2D. We’ve used the TMachines ActiveX 2D optimisation engine to integrate directly with our existing distribution software. It’s allowed us the flexibility we needed, and was simple to use, more importantly it’s allowed us to use a varying array of machines and manual processes with varying levels of complexity to be optimised by a single engine, and to integrate with our off-cuts. Not only that, but it consistently outperforms other optimisation engines in both speed and utilisation. We’ve managed to reduce our waste and make our staffs jobs easier, and it would not be possible without TMachines.

CutLogic 1D software was implemented last year in one of the divisions (Zamil Steel Tower and Galvanizing). Since implementation users are well satisfied with the system functionalities. CutLogic 1D application proved to be very successful as compared to earlier” optimizer” solution. In fact Zamil Steel management is considering implementing in other divisions Structure Steel on later stage.

This software has many advantages and by using this application, wastage has reduced. Beside built-in features, TMachines added on request additional functionality as was asked to do so. This software is flexible for customization according to user’s need. During implementation & after, we received excellent support from TMachines in terms of customization and installation. Zamil Steel is committed to use this software and also expecting future enhancement which can benefit not only to Zamil Steel but other users in the world. We’ve been using Cutlogic for about 6 months and it has already paid for itself many times over! For years, we have used spreadsheet models to determine our “optimal” cutting patterns.

As a former student of linear programming, I knew there was a better way. But, Cutlogic has exceeded my expectations. Our scrap is routinely about half what it was. And the superior results are being achieved in far less time, thus freeing up our staff to do more productive things than trial and error optimization.

Best Sheet Metal Cutting Tool

We have been using the CutLogic 2D program for a few years now. It has changed the way we look at the yield of our raw material. We are now able to order enough special material for each job and eliminate a lot of waste and inventory cost at the same time.

Laser Sheet Metal Cutting

The material cutters also like the product because it give them a detail of how to maximize each sheet and eliminate scrap. Thanks to the program, profits are up and scrap it down. I would recommend this program to whoever cuts full sheets of material.